Screw Conveyors | Food and Chemical Processors

Our process for the designing and manufacturing of specialized stainless steel screw conveyors is very comprehensive and provides solutions for our customers. One example of feedback we’ve received is “The augers arrived, they look great and are exactly what I expected. Not sure I could have got it done anywhere else as good as you guys did. I’ll definitely be coming back to you in the future for any other augers I may need.” We’ve worked with many food and chemical processors to dramatically improve their production time by offering customized screw conveyors that meet very specific needs.

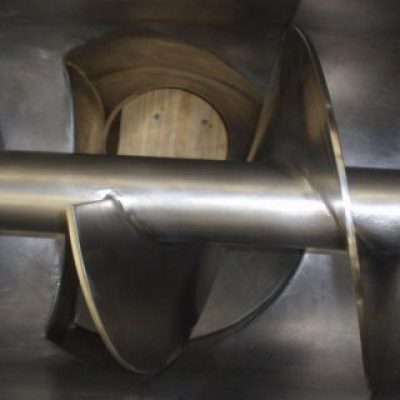

One of our specialties is the heavy duty stainless steel screw conveyor made with sectional flighting. With the auger, U troughs with hinged covers are most often employed for use in the food industry along with the motors and drives needed. Tool-less dismantle for easy wash down is also a standard feature. As a result, the flighting can be designed for mixing, compressing, or even heating or chilling. Inlet and outlet chutes are designed and built to work with existing or other new equipment being installed. Certainly, our design library has become extensive over the years making so we can quickly provide a good option for your situation.

Scope of Work

- Most auger systems are built with 304 grade stainless steel

- 2″ to 36″ in diameter

- Will provide complete systems or just the auger

- Only top notch motors, gear-reducers, and bearings are used in our screw conveyors

- Inlets and outlets custom designed to work with your installed equipment

- Food grade, bead blast, and other finishes

- Variable speed operation

- Variable pitch, mixing, notched flighting available

- Heated and chilled auger systems (The Thermoveyor)