Radiator Covers

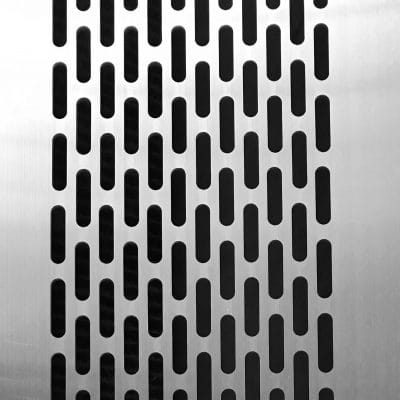

Radiator covers are fabricated in a variety of styles and punch patterns. For instance, some are matched to existing covers while other architects call for a new design. Some covers are attached to the wall, while others are freestanding, as well. The first step in creating the perforated covers is to field measure followed by drafting and designing for both the covers and the brackets for the situation. Then, after gaining customer approval, the radiator covers are punched and formed. Sometimes spot welded is needed, too. It’s important to know, Astro has all the equipment needed to fabricate completely on-site. Thus, we retain full control over the project without shipping to outside services. Lastly, most all of our radiator covers are made of 304 2B stainless steel with a brushed finish.

Applications & Uses

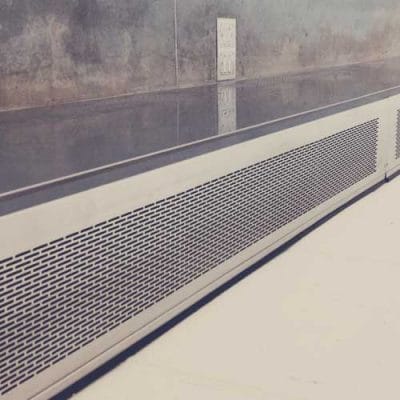

The perforated radiator covers for the Minneapolis – St. Paul International Airport presented their own unique set of challenges. These were, however, not immediately obvious to the naked eye. To create these covers, we accommodated several uneven surfaces. This is because the radiators were at variable heights on the walls and floor. By implementing adjustable supports and brackets on our perforated metal panels, we fit all of the different radiator cover configurations.

Scope of Work

- Field measurements for proper fit

- Perforations on the top and sides

- Match perforations of existing covers

- 16 & 18 gauge stainless steel

- #4 brushed finish

- Custom style to cover radiators that run along walls and stand alone

- Protective vinyl to keep scratch-free during installation