Perforated Metal Panels

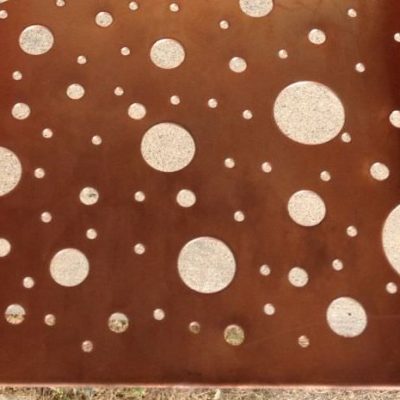

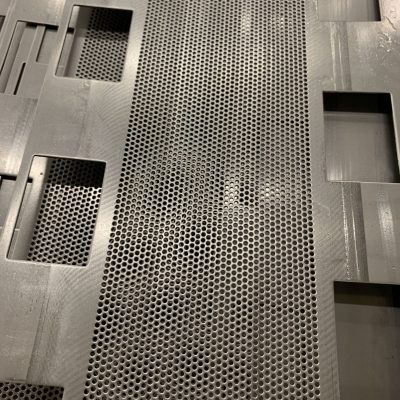

Architectural perforated metals are for ornamental, decorative metal projects. For example, from balcony railings to parking ramp cladding, and exterior building cladding to interior applications. For this purpose, perforating the metal sheets is just the first step of fabricating a complete panel. We have a complete fabricating facility that besides metal perforating, includes laser cutting, forming, saw cutting, machining and extensive welding experience and equipment. Furthermore, we work a lot with stainless steel, aluminum, and weathering steel. Having this experience and capability all on our site, we can fabricate efficiently, manage change orders, produce quality metal fabrication, and meet schedules. Our goal is to WOW our customers.

Applications

RAILINGS WITH PERFORATED METAL INFILLS

Guard railings with perforated metal infill panels along balconies and stairs gives a more secure feeling along with providing beautiful aesthetics. Schools, office buildings, condominiums, and apartments, and other commercial spaces are the popular place to use perforated metal railings. See our predesigned system complete with BIM models in our StellarCraft line.

Sunshades

While there are a lot of ways to make a sunshade, the use of perforated metal panels is a unique and fun way to filter light both light and air movement. Not only can an interesting pattern be created just on the panel itself, but also on the interior of the building as the light shines through to the floor or wall.

FENCES

By mounting perforated metal panels to posts, a beautiful little to no-maintenance fence can be created. A perforated metal fence is especially useful where a division in an outdoor public space is needed. See our page on Perforated Metal Fences for more information.

RADIATOR COVERS

Radiator covers are another product that Astro fabricates, including many of them for the MSP airport. The first steps prior to fabrication are: field measuring, drafting and design for fabrication. After the sheet metal is cut to size, it is perforated, formed, welded, finished, and lastly, installed. We can match existing radiator cover patterns and build to fit the contour of the space.

PARKING RAMPS

The use of perforated metal panels is very popular for parking ramps, indeed! With the increase of cities that now require interior lighting plus screening from the exterior, architects are using perforated metal panels to meet the requirements. Nevertheless, these metal panels provide a beautiful, durable, and long lasting exterior for parking ramps.

COLLABORATIVE DESIGN FOR PERFORATED METAL PROJECTS

With years of experience in the metal fabrication industry, our team of engineers and project managers offers design assistance. We help work out those design details that can make or break a project and can assist with bracket design, metal choice and gauge, perforation patterns, and more. Our goal is to make you and your project look great, fit your budget, and solve your problem.

FINISHING AND INSTALLATION

Astro also partners with finishers and installers for completion of the architectural work we fabricate. Hence, we focus on the fabricating and can offer our products in whatever coating the job calls for. Some of the common choices include anodizing, painting, or powder coating for aluminum. Further, galvanizing with or without paint for carbon steel, and no finish for weathering steel. For stainless steel, #4 brushed finish is most common.

Call us today at 763-777-8087 to discuss your perforated metal product needs.