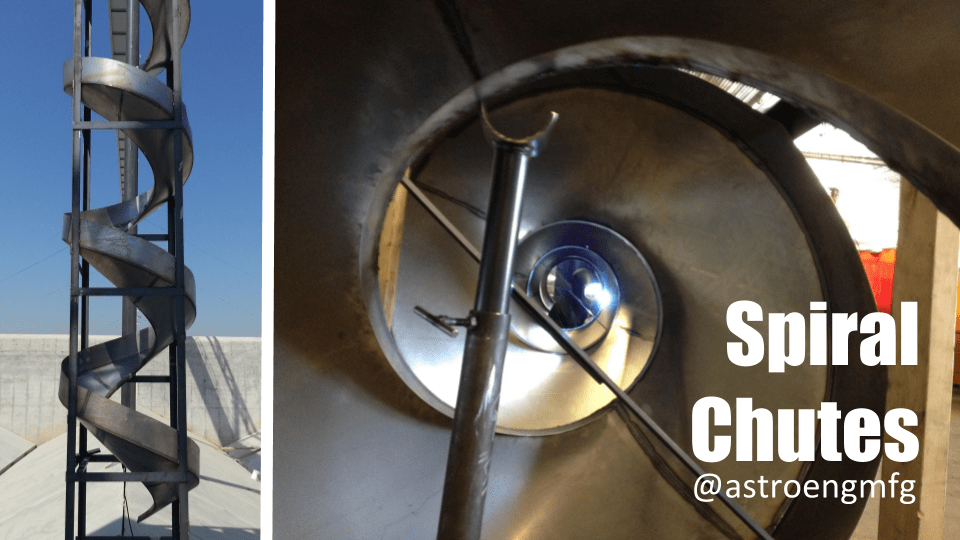

Metal Forming Expanded with New Press Brake!

Exciting news from Astro! Our new 350 ton PRESS BRAKE has arrived! We are thrilled our metal forming has expanded with our new press brake. It’s increasing our forming capabilities and our overall metal fabricating capabilities. Just two days after arriving on the truck, we are already putting the new press brake to work on forming ½ thick plate steel. It’s using about 150 tons for this job, so you can see there is still 200 ton capacity available for bending thicker or longer metal.

The Role of a Press Brake in Metal Fabrication

Our metal forming capabilities has definitely expanded with the new press brake! Such as, the ability bend thicker and longer pieces (up to 14 feet) of metal, in-house. Both our architectural and industrial equipment clients reap benefits here. We are excited about the increase in capability we offer in metal fabrication, along with the increased safety features of this machine.

Machining, Welding, Laser and Forming

Metal forming, or bending, is one of the integral components of sheet metal fabrication. Fabrication often begins with laser cutting or punching, followed by the press brake, then welding. Machining usually takes place just before or after welding, and sometimes both. The more components that can be formed as opposed to welded greatly increases output efficiency of the fabrication process. Decisions as to whether parts are formed or welded are made at the engineering, drafting, and design stages. This is one area we pay close attention during the design process to be able to reduce cost and increase quality.

If you have a need for these metal fabrication services, we’d love a chance to talk to you. Give us a call today.