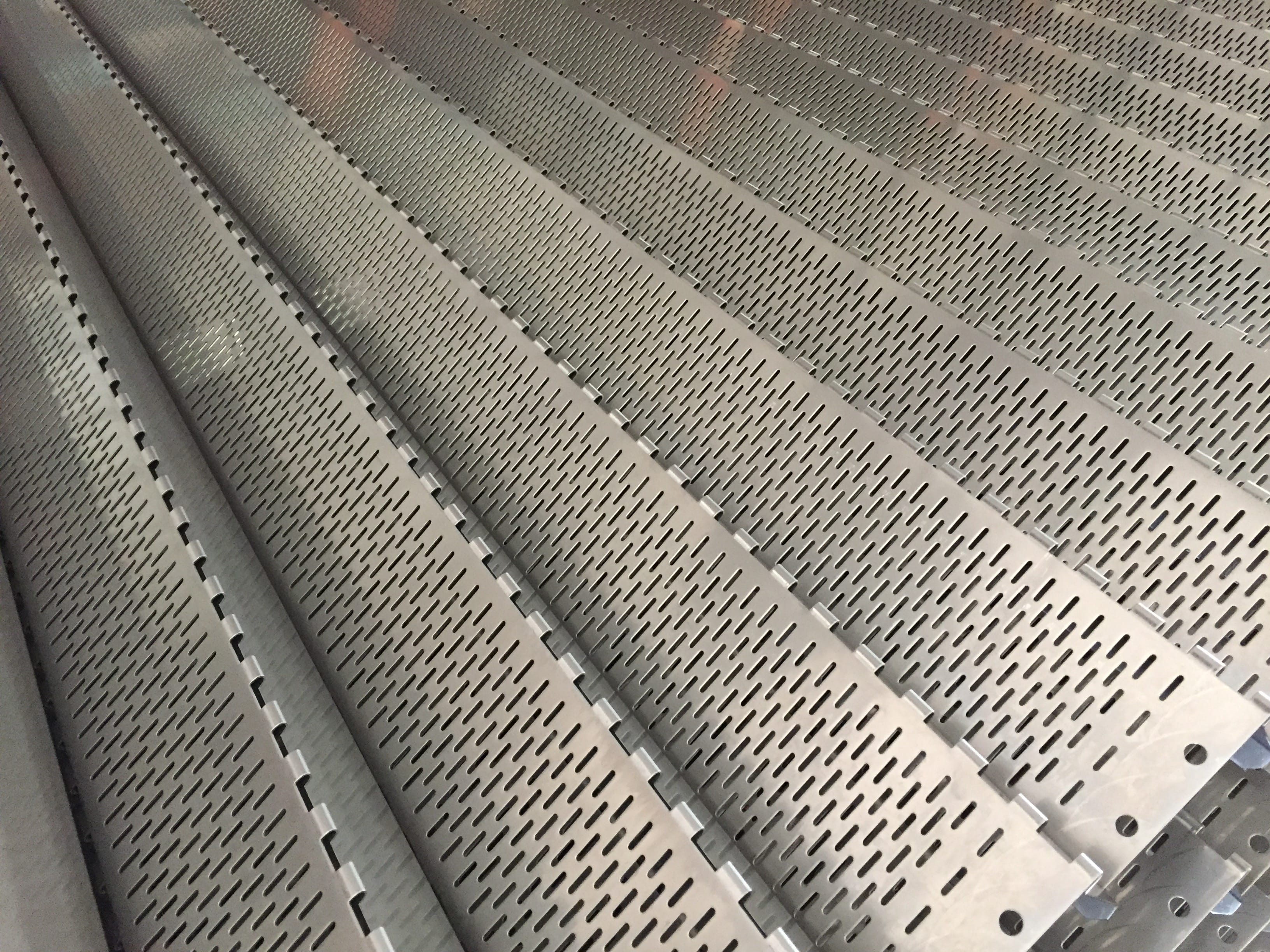

CWI and Certified Welding Capabilities

Global interest in reliability and public safety has stimulated the expansion of certified welding. Certified welding is welding under previously tested and proven parameters and conditions. Because welding affects various joined materials, including metallurgical and dimensional changes, a Certified Welding Inspector (CWI) ensures the weld is going to be up to the task of its intended design. Nevertheless, having a CWI and certified welding capabilities confirms the highest level of quality workmanship by providing direction for making sound and superior welds.

So, what’s so difficult about welding? Welding is welding, right?

The sheer number of variables that go into performing a weld is what makes this tricky (to say the least). Some of these variables include: joint geometry; metal and filler material chemistry; surface conditions; travel speed and wire feed speed; torch angle; welding current and arc voltage; polarity; shielding gas used and its flow rate; and, of course, many more. Many knowledgeable, skilled and experienced welders without CWI-level training know how to adjust their machines and techniques to deal with these variables, but at various levels of competence and outcomes. A certified welding inspector’s vast knowledge and experience with welding processes, procedures, qualifications, and materials, is paramount to bringing a metal fabrication facility to a new level of producing repeatable quality weldments.

AWS, ASME & API

Certifications and standards in this industry are through the American Welding Society (AWS), the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API). ASME and API are used for pressure vessels; however, AWS is a structural code. The major difference is that ASME is for welding procedure and welder qualification, while AWS provides the same assurances as ASME, but includes inspection, erection and fabrication. Specifically, our CWI here at Astro is certified through AWS.

Certification through AWS is achieved by satisfying a combination of education, experience, and examination requirements. Welding codes are designed to improve the quality and efficiency of welding. They are also used to qualify process and welders. This, in turn, controls the characteristics of the welded component to ensure its service requirements. Therefore, we use them to assist in the development and implementation of our welding quality management system.

CWI and Certified Welding Capabilities

D1.1 STRUCTURAL WELDING CODE – STEEL

This code is for design, procedures, qualifications, fabrication, inspection and repair of steel structures. This is especially important for engineers, detailers, fabricators, erectors, inspectors, and anyone else involved in any phase of welding steel structures.

D1.2 STRUCTURAL WELDING CODE – ALUMINUM

This covers the welding requirements for most structures made from aluminum structural alloys, except for aluminum pressure vessels and also pressure piping.

D1.3 STRUCTURAL WELDING CODE – SHEET STEEL

This specification covers arc welding of commonly used structural quality low-carbon hot rolled and cold rolled sheet and strip steel, with or without zinc coating (galvanized), to other structural sheet steels or to supporting structural steel members. It also covers the design, procedure and performance qualification, fabrication, inspection and stud welding as well.

D1.6 STRUCTURAL WELDING CODE – STAINLESS STEEL

This provides standardized requirements for welding stainless steel structural assemblies and components (excluding pressure vessels or pressure piping) using gas metal arc welding, shielded metal arc welding, flux cored arc welding, submerged arc welding, and likewise stud welding.

D9.1 SHEET METAL WELDING CODE

This code provides standardized requirements for the qualification, production, and acceptance of welding or braze welding of nonstructural sheet metal components. Please note: D9.1 and D1.3 have overlapping scopes. Because of this, our CWI always use D1.3 in place of D9.1

D14.3 SPECIFICATION FOR WELDING EARTHMOVING, CONSTRUCTION AND AGRICULTURAL EQUIPMENT

This specification provides standards for producing structural welds for earthmoving, construction, and agricultural equipment. Procedures assure base metals are welded with compatible, identifiable welding processes and consumables that affect weldability.

D14.4 SPECIFICATION FOR THE DESIGN OF WELDED JOINTS IN MACHINERY AND EQUIPMENT

This specification establishes common acceptance criteria for classifying and applying carbon and low-alloy steel welded joints used in the manufacture of machines and equipment.

D15.1 RAILROAD WELDING SPECIFICATION FOR CARS AND LOCOMOTIVES

This specification establishes minimum standards for the manufacture, maintenance, and reconditioning of railroad equipment, such as railroad cars, locomotives and passenger cars.

About Us

Astro Metal Craft has an AWS certified welding instructor on staff to ensure reliable, certified welds. Whether your projects requires certified welding or not, know that Astro will always provide the best welding for your job, no matter how big or small the project. Hence, contact us today for your next welding assignment. We love to help!