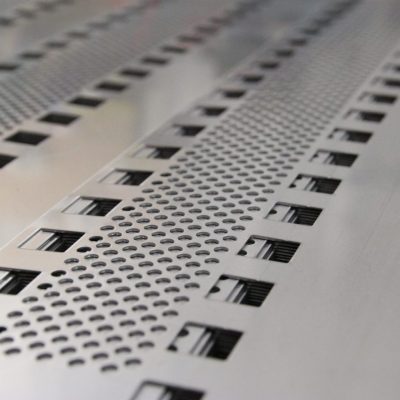

Perforated Metal Screens

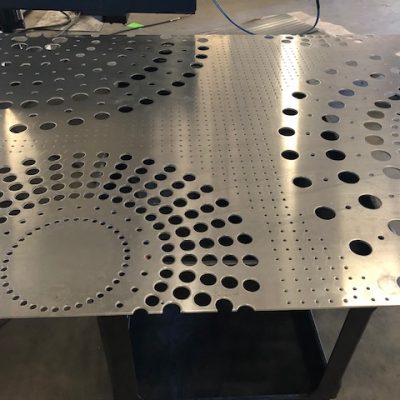

Perforated metal screens have a wide variety of use for both architectural and industrial purposes. Automation using CNC punch machines makes it possible to produce affordable custom perforated metal screens which usually goes into a product. Here at Astro Metal Craft, we can perforate sheet thickness ranging from 22 gauge to ¼ inch utilizing Trumpf machines. The TruPunch 5000 is top of the line for speed and accuracy. It can run up to 1600 strokes per minute, has an active die ensuring low-scratch parts, and hold up to 16 punches for shape variety. In addition to the perforating, Astro offers full fabrication services including forming, laser cutting, welding, machining, and finishing to produce a finished product.

Applications

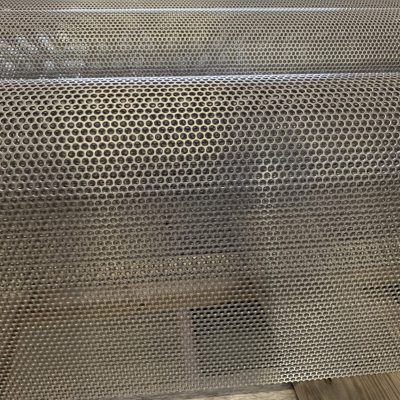

For industrial purposes, perforated metal screens are often used filtering particles from liquid.

We specialize in perforating industrial screens for the food processing industry, the gas and oil industry, and water treatment industry. Most of these industries utilize perforated stainless steel sheet which are then fabricated into specific proprietary parts and machinery. Our clients depend on us to perform both the perforating and full fabrication for their machinery needs.

Cooking equipment, lighting fixtures, air diffusers, ventilation grilles are other examples where industrial perforated metal screens are used.

See our page on Industrial Perforated Metals for more information.

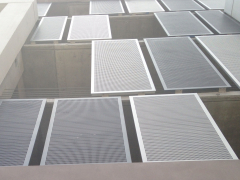

Perforated metal screens are also used extensively in architecture applications. In architecture, airflow, light, sound, and the view are filtered. Additionally, perforated metal screens add structure, a physical barrier, and interest to the space.

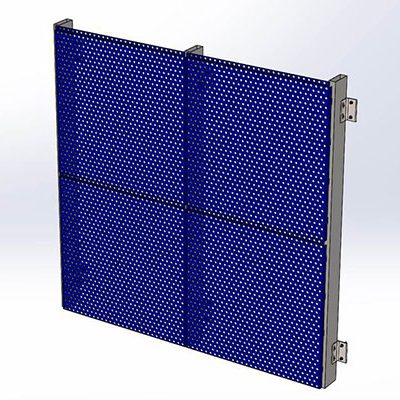

Sunshades can be applied horizontally, vertically, or at an angle to provide shade and protection from the elements above windows, on a pergola, or sides of a building.

Security panels can be applied to windows or vulnerable areas of a building where security is a concern. Perforated metal screens are a creative, decorative addition to the building while adding protection. They can be designed to the owner’s specifications and can be removeable or permanent.

Rainscreens create a level of protection on a building exterior. Perforated metal screenings can create a unique effect while protecting a valuable structure.

Ceiling panels can be made of perforated metal screens. It adds a decorative touch with color and punch pattern customized to the application. Can be used with or without sound dampening material.

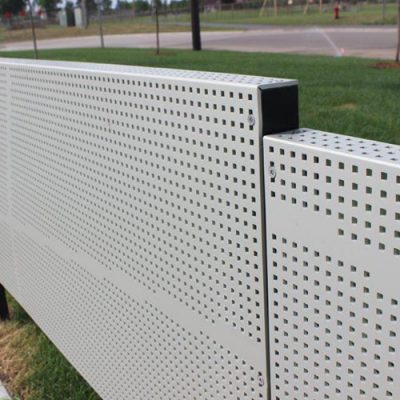

Fencing is another popular way that perforated metal screens are used. Considered a permanent no to low-maintenance solution for property lines, public space divisions, and more. See our perforated aluminum fencing page for details.

Materials and Perforating Parameters

Aluminum and Stainless steel are the two most common metals we perforate, although basically any metal sheets can be perforated.

Being we are a custom shop working for a variety of industries, our punch takes sheet stock as opposed to coil stock. Our engineering department determines the best sheet size for the project to eliminate waste. Our machines can accommodate sheet size up to 5’ X 12’.

Some rules of thumb in determining what can be punched:

- Hole diameter need to be the same or greater than the material thickness

- Hole size can be up to 3” diameter if the tonnage doesn’t limit that. Tonnage is determined by sheet thickness and material type and grade.

- Distance between openings must be at least the thickness of the material being punched.

- Shape choices, mixture of shapes, including louvers and borders, make up an infinite variety of perforating possibilities.

Our engineering department reviews all projects prior to commencement to ensure success. We welcome inquiries about the manufacturability of your project. Contact us today for more information.