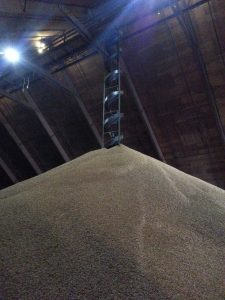

Protecting Delicate Food Products with Spiral Chutes

In the food processing industry, maintaining product integrity is paramount. For delicate items like crackers, pasta, cereals, and snacks, even minor jostling during transport can lead to breakage, resulting in waste and lost profits. That’s where the gentle touch of spiral chutes, also known as gravity chutes or spiral letdowns, make all the difference.

A Controlled Descent for Fragile Foods

Unlike traditional conveyors that can cause product agitation and impact, spiral chutes utilize the power of gravity for a smooth, controlled descent. The food products gently spiral downwards, minimizing contact and reducing the risk of damage. This controlled movement is crucial for preserving the quality and appearance of fragile food items.

Why Choose Spiral Chutes for Delicate Products?

Spiral chutes are designed to ensure a consistent and gentle flow, reducing the chances of products bumping against each other or the chute walls. Astro has many years of experience in engineering and fabricating spiral chutes. We are able to custom design each chute for any application, depending on the customer’s needs. There are several variables that go into designing a chute that is efficient and cost effective. Essentials such as volume, speed, inlet and outlet chutes, frame structure and height all play a factor in delivering products in a rapid yet controlled manner.

By minimizing agitation, spiral chutes significantly decrease product breakage, leading to less waste and a higher yield of marketable product. This is particularly important for products with high value or those sold by piece count. The gentle handling preserves the product’s shape, texture, and overall quality, ensuring it reaches consumers in optimal condition.

In some applications, like bin filling, there is a potential for product spillover. Well-designed spiral chutes often incorporate features to contain any spillover within the chute itself, ensuring a gentler landing and minimizing further damage. From dry goods like crackers and cereals to more delicate items like pasta and even some frozen prepared foods, spiral chutes offer a versatile solution for a wide range of food products.

Beyond Reduced Breakage: The Benefits of Gentle Handling

The benefits of gentle handling extend beyond simply reducing breakage. It also contributes to:

-

Improved Product Presentation:

Intact products present better on store shelves, increasing consumer appeal.

-

Increased Customer Satisfaction:

Consumers expect products to arrive in perfect condition. Spiral chutes help ensure that expectation is met.

-

Reduced Rework and Downtime:

Less breakage means less time spent cleaning up spills or re-processing damaged goods, leading to increased efficiency and reduced downtime.

For food processors looking to minimize waste, maximize product quality, and improve overall efficiency, spiral chutes offer a compelling solution.

Ready to see the difference a spiral chute can make for your products? Contact Astro Metal Craft to help design the perfect spiral chute for your products. Come test your products on our spiral chutes and experience the benefits firsthand.