Tube Laser Shop Talk

Ever wondered how a tube laser actually works? In our newest ‘Shop Talk‘ video, operator Gordon broke it down with a brilliant example! Think back to when you were a kid, using a magnifying glass to focus the sun’s rays, maybe to burn a tiny dot on a leaf or draw on paper. Gordon explained that our laser uses that exact same concept. Take some intensely focused energy, add a few specialized gases and introduce a burst of power – and you have yourself a tube laser!

Decoding “LASER”

The word “LASER” is an acronym that stands for: Light Amplification by Stimulated Emission of Radiation.

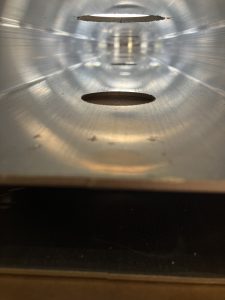

The tube laser utilizes a gas-filled tube with highly reflective mirrors at both ends. Energy is introduced into this tube, which leads to the emission of light particles. These particles bounce back and forth between the mirrors. One of the mirrors is only partially reflective. As the energy within the tube intensifies, a concentrated beam of amplified light escapes through the partially reflective mirror to form the laser beam.

Primary Function

The primary function of our tube laser is to cut parts. Its capabilities extend far beyond straight lines. The machine can precisely cut a range of styles, including round, square, rectangular, L-shaped, and many more diverse shapes.

One of the most significant benefits of having these capabilities in our shop is the ability to streamline the manufacturing process. No longer does a part need to be shuttled between multiple machines for different operations. The tube laser can perform a multitude of tasks in one single setup.

How does this powerful tool get to work? Here’s a glimpse into the setup process:

- Material Loading: The raw material, whether it’s a tube or pipe, is placed onto the automated loader.

- Feeding the Beast: The loader then precisely feeds the material into the laser cutting machine.

- Brain Power Activated: The machine’s computer is programmed with the specific cutting instructions.

- Essential Checks: Crucial consumables, such as the delicate laser tube, focusing nozzles, and protective lenses, are meticulously checked for safety and optimal functionality.

- Ready to Go! Once these steps are complete, the tube laser is primed and ready to execute intricate cuts.

The machine operates using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) drawings. These digital blueprints precisely dictate every cut the laser needs to make. This information is uploaded and programmed into the machine’s computer before the cutting process begins.

Navigating Dimensions: 2D vs. 3D Cutting

Our tube laser is capable of making both 2-Dimensional and 3-Dimensional cuts. What sets them apart is the specific cutting plane the laser is programmed to follow. 2D cuts are performed on a single plane, while 3D cutting allows for angled cuts, bevels, and intricate features that require the laser head to move along multiple axes.

The tube laser is a testament to the incredible advancements in metal fabrication technology, and we’re proud to have this capability right here at Astro Metal Craft. Stay tuned for our next shop talk video to find out more insights into our innovative processes at Astro Metal Craft!

Check out our full Tube Laser YouTube Video!!