TruPunch 5000 Shop Talk

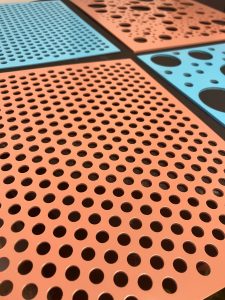

=In our latest YouTube video from the Shop Talk series, we had the chance to spend an exciting day with Cole, diving deep into perforated metal and the inner workings of the TruPunch 5000. Whether you’re a professional fabricator or someone looking to learn more about cutting-edge technology in manufacturing, this video is a must-watch.

The TruPunch 5000 is not just another perforated metal punch machine. It’s the backbone of the shop floor, setting the tone for productivity, speed, precision, and even style. It is designed to handle a wide variety of materials, from steel and aluminum to bronze and brass. The TruPunch 5000 can handle materials ranging from paper-thin sheets to quarter-inch-thick metal, making it incredibly versatile. No matter what material you’re working with, this machine has you covered.

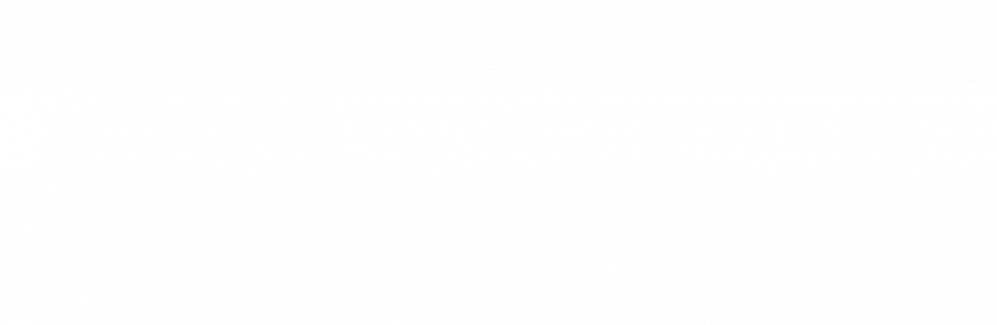

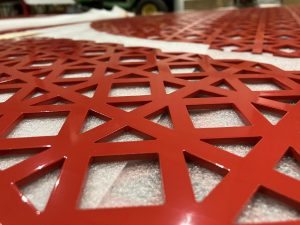

Custom Patterns for Perforated Metal

One of the most compelling features of the TruPunch 5000 is the endless possibilities for perforated metal patterns. When a design is created, custom-patterned tools are ordered and installed directly onto the punch machine. From there, the machine gets to work, punching out the specific pattern and design. Common patterns include round, square, triangle, diamond, and many more. What makes this piece of equipment so valuable is its use of cluster tools. Cluster tools allow up to 4 holes to be punched simultaneously. This increases efficiency, allowing jobs to be completed faster without sacrificing precision.

Depending on the specific pattern features needed, the TruPunch 5000 can punch up to 1,600 strokes per minute. This kind of efficiency not only saves time but also boosts productivity, enabling quicker project turnaround times.

Forming Capabilities

After a hole is punched, a forming tool and spring-loaded die can be applied to manipulate the metal and create custom forms. This gives you the ability to add a variety of shapes and features to your parts, making it an all-in-one solution for more complex projects.

Why the TruPunch 5000 is a Shop Floor Essential

In today’s fast-paced manufacturing environment, having the right equipment is essential for staying competitive. The TruPunch 5000 brings together productivity, speed and precision, making it an indispensable tool for projects that need to tackle a range of tasks with efficiency.

For a closer look at how the TruPunch 5000 operates, be sure to check out the full video in our Shop Talk series. Stay tuned for more in-depth insights and equipment breakdowns in our next Shop Talk episode.

Check out our full TruPunch 5000 YouTube Video!!