Architectural Metal Panels

Metal Panels are widely used in a variety of building projects for a variety of purposes. They are protective, virtually maintenance free, long-lasting, and decorative. Architects and contractors rely on our expertise to fabricate and supply the various types of metal panels needed for architectural use. Perforated metals panels are a top choice for several applications due not only to the customizable and stunning effect created on the exterior of a structure, but also because they provide some protection from the elements along with enabling light and airflow. All our panels include an engineered bracket mounting system to assure successful performance.

Applications

Metal panels are used extensively on building exteriors as façade cladding, rainscreens, rooftop screening, sunshades, security panels over windows, and plant trellises. Metal panels also are incorporated into guard railings and metal fences, used as screening, and installed on interior ceilings and walls. We are routinely delighting our customers in providing the architectural metal panels that meet the quality and performance standards of the project.

Materials

Aluminum is generally the most popular choice due to being lightweight, nearly no-maintenance, and cost effective. It is quite essential that a coating be applied to aluminum before installation to keep it looking in excellent condition for many years. A polyvinylidene fluoride (PVDF) coating is the most durable and fade resistant coating available. We work with several painters to be able to offer a wide variety of color choices in this type of coating. Anodizing is another way to keep aluminum panels looking beautiful for years but can run into challenges of unevenness in color. Still, a beautiful effect is created if slight color variation is accepted as part of the design.

Stainless steel is another metal used for metal panels. It’s totally the right material when a shiny metal surface is desired, and the application warrants its use, and the slightly higher cost can be accommodated. Stainless steel can be mechanically finished in a variety of ways to create a striking effect on any surface.

Copper metal panels of are beautiful, although adds significant cost.

Weathering Steel is a popular choice for perforated panels on building exteriors such as parking ramps, or wall screening. The cost is significantly lower than both coated aluminum and stainless steel. With weathering steel, the surface of the metal will rust, but only to a slight degree to create a durable protective surface.

Carbon steel panels would be the lowest cost, but only used either indoors or when cosmetics are not important. Even with a good coating, driplines of rust will eventually occur at fastening joints in most all outdoor uses.

Types of Metal Panels

Solid sheet metal panels are also formed (bent) on the edges for strength, to provide a clean edge, and a place to attach the mounting brackets. For use when full solid coverage is needed. As with any type of metal panel, the gauge, or thickness of the sheet is determined by the engineering calculations to ensure a strong stable surface that will hold up to the intended use.

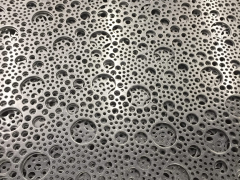

Perforated metal panels and laser cut panels are used in places where airflow and light passage is desired. The affect achieved with light showing through the panels is beautiful and memorable. There is an infinite number of patterns and design that can be incorporated to make the space truly unique and striking. We work with designers and architects to help determine suitable patterns for the space. Our CNC punches and lasers enables us to fully complete the project in-house.

Wire mesh panels is yet another option for filling a space. The wire can be either woven or welded and comes in a wide variety of gauges and openness. The typical use for these is as infill panels for either guard railings, equipment enclosures, or ceilings. The edges will have a U-wrap edging to cover the wire ends and provide a finished look. Astro Metal Craft, being a full fledged metal fabricator, completely fabricates the project and sends to the site ready to install.

We work with architects, designers, and builders to provide solutions for attractive and functional metal panel design complete with mounting systems. The fabrication is done at our shop in Hanover giving us control over quality and schedule to meet the clients’ needs. Install is provided as desired.

See our StellarCraft pages for a series of pre-designed panel and fencing options complete with specifications and BIM models.